System Design & Equipment Layout

WHEN MISSION READINESS DEPENDS ON PERFECT DESIGN.

VES Corrosion Control Facility Design Services - Decades of Military Aircraft

Maintenance Expertise Applied to Modern Facility Design

Military corrosion control facilities aren't just buildings—they're critical infrastructure where aircraft readiness and personnel safety intersect. Traditional architectural firms understand construction, but they don't understand the intricate operational requirements, compliance complexities, and mission-critical nature of corrosion control operations.

VES bridges that gap with decades of hands-on expertise.

MILITARY-TESTED DESIGN EXPERTISE

Proven Operational Experience: Decades of involvement in military aircraft maintenance and corrosion control facility design projects worldwide. We don't just design facilities—we understand how they must operate.

Architecture & Engineering Collaboration: Direct partnership with A&E firms ensures

efficient coordination and modernized facility designs that integrate seamlessly with overall

project goals.

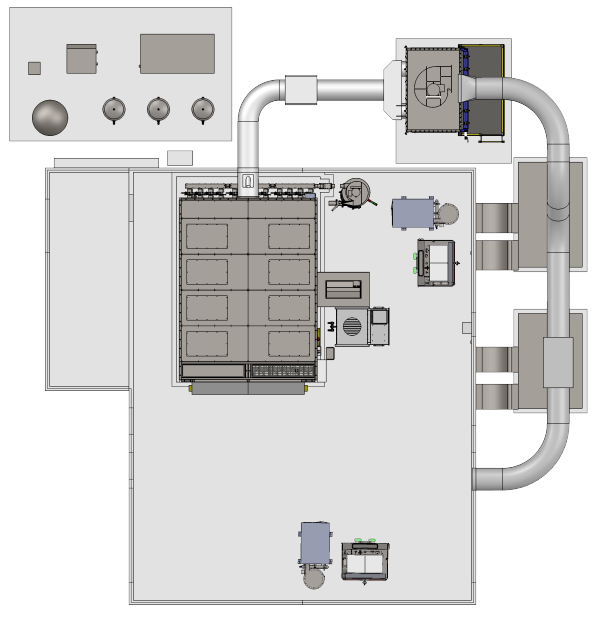

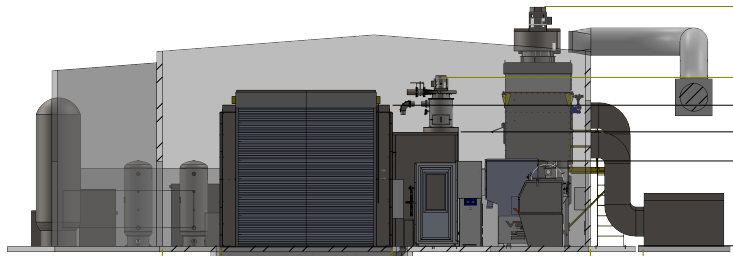

COMPREHENSIVE DESIGN CAPABILITIES

Facility Operational Flow Optimization: Expert recommendations ensure streamlined, safe,

and efficient operations within your corrosion control facility. Every workflow, every traffic

pattern, every operational sequence optimized for maximum efficiency.

UFC Compliance Mastery: Designs that fully comply with UFC Section 2-4 requirements,

including precise “Hot”, “Warm,” and “Cold” zone separation that protects personnel and

maintains regulatory compliance.

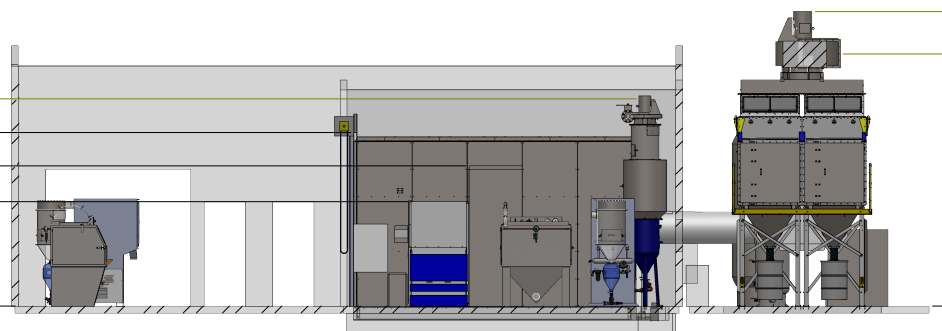

Specialized Equipment Integration: Complete identification and integration of mission-critical systems:

PAINT & STRIP OPERATIONS INFRASTRUCTURE

- Paint Hangars & HVAC Systems engineered for optimal environmental control

- Paint Strip Facilities and Equipment designed for maximum efficiency and safety

- Paint Storage & Mixing Rooms with proper ventilation and safety systems

PRECISION SYSTEMS ENGINEERING

- Small Parts Paint & Blast Systems for component-level operations

- Seismic & Structural Analysis ensuring facility resilience

- Advanced System Controls for automated, reliable operation

- Compressed Air Systems sized and designed for operational demands

CONTAMINATION CONTROL SYSTEMS

- Air Showers for personnel decontamination

- Full Facility Integration ensuring seamless system operation

- Dust migration tracking

- Hazardous dust remediation

OPERATIONAL SUPPORT DESIGN: Complete recommendations for shop tools and

supporting equipment essential for efficient operations: material racks, specialized hand tools, hazardous storage solutions, work benches, and operational support equipment.

COMPLIANCE & STANDARDS EXCELLENCE

Comprehensive Regulatory Adherence: Every VES design aligns with critical standards and

requirements:

SAFETY & ENVIRONMENTAL STANDARDS

- OSHA CFR-2017-Title29-V5-Part 1910

- NESHAP 40 CFR Part 63 Subpart GG

- SMACNA ANSI/SMACNA 005-2013

- ASHRAE 2019 Handbook standards

VENTILATION & FIRE SAFETY

- ACGIH Industrial Ventilation 30th Edition

- NFPA Sections 30, 33, 652, 70, 400

- UFC 3-410-04 Industrial Ventilation requirements

MILITARY SPECIFICATIONS

- US Military Corrosion Control Reference Guide

- Air Force Corrosion Control & Fuel Cell Maintenance Hangar Facility standards

- Air Force Advanced Composite Repair Facility Guide

- TO 1-1-8 Application and Removal of Organic Coatings

- UFC 4-211-02 Aircraft Corrosion Control and Paint Facilities

THE VES ADVANTAGE

INNOVATION WITH EXPERIENCE: Integration of industry's latest technologies and

systems with proven operational knowledge—maximum performance based on real-world

understanding.

MISSION-CRITICAL FOCUS: Every design decision made with long-term mission readiness and operational efficiency as primary objectives.

COMPLIANCE CERTAINTY: Comprehensive understanding of U.S. Government and UFC

requirements eliminates costly redesigns and compliance issues.

COLLABORATIVE EXCELLENCE: Direct coordination with A&E firms streamlines the design process and ensures optimal integration of specialized corrosion control requirements.

THE BOTTOM LINE: MISSION SUCCESS

When war readiness depends on your corrosion control facility, design flaws aren't just inconvenient—they're mission failures waiting to happen. Traditional architects design buildings. VES designs operational success.

With VES facility design services, your corrosion control facility doesn't just meet requirements—it enables mission excellence.