"OUR PRIMARY GOAL IS THAT THE OPERATOR CAN SAFELY DO THE MISSION WITH THE RIGHT PROTECTION IN PLACE"

By Jonathan Allred - Aerospace & Defense Review

Daniel Myers, president of Veteran Equipment Sales (VES), is a service-disabled veteran who believes the people who keep aircraft mission-ready deserve the same level of protection as the aircraft themselves.

That belief was forged over decades in aircraft sustainment, from his early service in the United States Air Force to his later role at a major aircraft depot facility. There, every strip, blast, and repaint demanded absolute precision, yet the environments supporting that work often lagged far behind the hazards involved.

Throughout his career, Myers repeatedly saw technicians performing high-risk corrosion control

tasks in outdated facilities with poor airflow, improperly sealed equipment, and a lack of knowledge on hexavalent chromium, exposing them to toxic dust and longterm health consequences. Safety was treated as an individual responsibility rather than an engineered condition. Watching skilled operators shoulder risks that engineering progress should have already eliminated shaped his conviction that protection must be designed into the environment, not delegated to behavior.

VES, an SBA-certified Service Disabled Veteran Owned Small Business based in Idaho, now carries that conviction forward. The company designs and manufactures integrated corrosion control environments for aerospace, defense, mining, and other industrial sectors. Its systems combine controlled spaces, engineered airflow, and operator protection into a single, unified solution built around one principle. People come before products.

“Our primary goal is that the operator can safely do the mission with the right protection in place,” says Myers

When Exposure Becomes Structural

The dedication to operator safety at VES comes from real-world experiences. Myers witnessed the long-term consequences of exposure firsthand. He saw retired depot workers develop cancers years after leaving service. In one case, a former technician died of cancer suspectedly linked to hexavalent chromium exposure. As told to Myers, later, his spouse’s home and car tested positive for hexavalent chromium contamination, most likely traced back to dust unknowingly carried home by the employee

on his clothing and shoes.

These were not failures of discipline or compliance. They were failures of system design. Contamination followed workers home because environments relied on procedures and PPE rather than engineered solutions for containment and elimination. Over decades of exposure, written policy could not compensate for structural gaps. For Myers, that reality made safety non-negotiable.

Hexavalent chromium is not a marginal risk. The Erin Brockovich case drew attention to the chemical,

which Myers characterizes as far more carcinogenic than asbestos. Yet in many facilities, primary controls still depend on respirators, housekeeping routines, and signage. VES was founded on the belief that real protection only exists when systems assume procedures will break down and are engineered to help prevent exposure regardless.

People Before Products, Engineered into Practice

VES operates on a clear philosophy. PPE and policy are necessary, but they cannot be the final safeguard. Engineering must be the last line of defense.

That philosophy shaped the company from the beginning. Myers launched VES in 2015, and after a planned acquisition fell apart, he moved into manufacturing advanced equipment in 2019. Free from legacy assumptions, the company was built around one core belief; protection should never be optional or retrofitted. It must be built into the environment surrounding every technician.

This approach reframes change management. Instead of relying on training refreshers or compliance enforcement, VES embeds safer behavior directly into how work is performed. Engineering decisions replace procedural dependence, reducing variability and risk over time.

Unifying Critical Systems with Governance Built In

In an industry where customers often juggle separate vendors for blast booths, air systems, and clean rooms, VES stands out as a full-support integrator.

Competitors typically deliver only one component of the corrosion control ecosystem, leaving customers to coordinate multiple contractors and assume the integration risk. VES eliminates that burden by delivering complete, end-to-end environments. These include blast and paint hangars, clean rooms, air showers, compressed air systems, and small parts paint and blast booths. When external components such as compressors are required, they are engineered into the workflow from the start.

Governance and procurement are treated with the same discipline. Many VES products carry National Stock Numbers, allowing government agencies to acquire equipment through established channels without extended competitive cycles. NSN listing is not a marketing credential; it signifies compliance, repeatability, and earned trust.

“The government trusts that the product does what it says it does and is competitively priced,” says Myers.

This trust is reinforced by operational consistency. At many military installations, Myers saw too many systems arrive that failed to perform as promised, driving post installation modifications that pushed budgets 30 to 40 percent over plan. VES designs every system to operate exactly as specified, without downstream correction or costly change orders.

“We understand our customers and their needs, and look to design and develop solutions that meet those needs,” says Vice President Roger Wilbanks.

That mindset drives long-term relationships. In one early project, a customer purchased a blast system configured for plastic media. When a more aggressive media was used, it damaged the equipment. VES built, shipped and installed replacements parts at its own expense to ensure the customer needs were fully supported, even though the original equipment was delivered as ordered.

“We will work out the minutia in the end, but we want you long term,” Myers says.

To protect customers operationally, VES uses commercial off-the-shelf components for controls and internal systems. If the company were ever unavailable, customers could still maintain equipment locally. Proprietary lock-in has no place in mission-critical environments.

Delivering Measurable Results at Scale

VES systems are already delivering tangible improvements in readiness, safety, and cost control.

In Tucson, blast capability upgrades were stalled by funding and procurement delays. VES collaborated with an 8(a) firm to create a viable contracting pathway and aligned technical specifications directly with mission needs. The facility is now under modification, equipment has been delivered, and installation is scheduled for early 2026. What could have taken years is being executed in months.

At Osan Air Base in South Korea, a newly constructed corrosion control facility entered service with severe ventilation and operational flaws. VES was engaged to assess the site. Its findings led the government to halt the original project and initiate a redesign with a leading architectural and engineering team. The contractor specifically requested VES to provide compliant airflow solutions and integrated advanced equipment, avoiding a potential multimilliondollar teardown.

VES also provides abatement through its Hex Buster™ technology, a “green” solution that permanently converts hexavalent chromium into trivalent chromium, a harmless nutritional mineral. The conversion is irreversible. Facilities that would otherwise close for months can reopen in days or weeks, shifting costs from millions to tens or hundreds of thousands while returning operators to mission work quickly.

Continuous Improvement, Not Complacency

Product and equipment evolution at VES is continuous. The Raptor cabinet line, first delivered in 2020, has undergone multiple design iterations focused on ergonomics, sealing, dust control, and durability. When improvements enhance safety, usability, or longevity, VES implements them and absorbs the development cost.

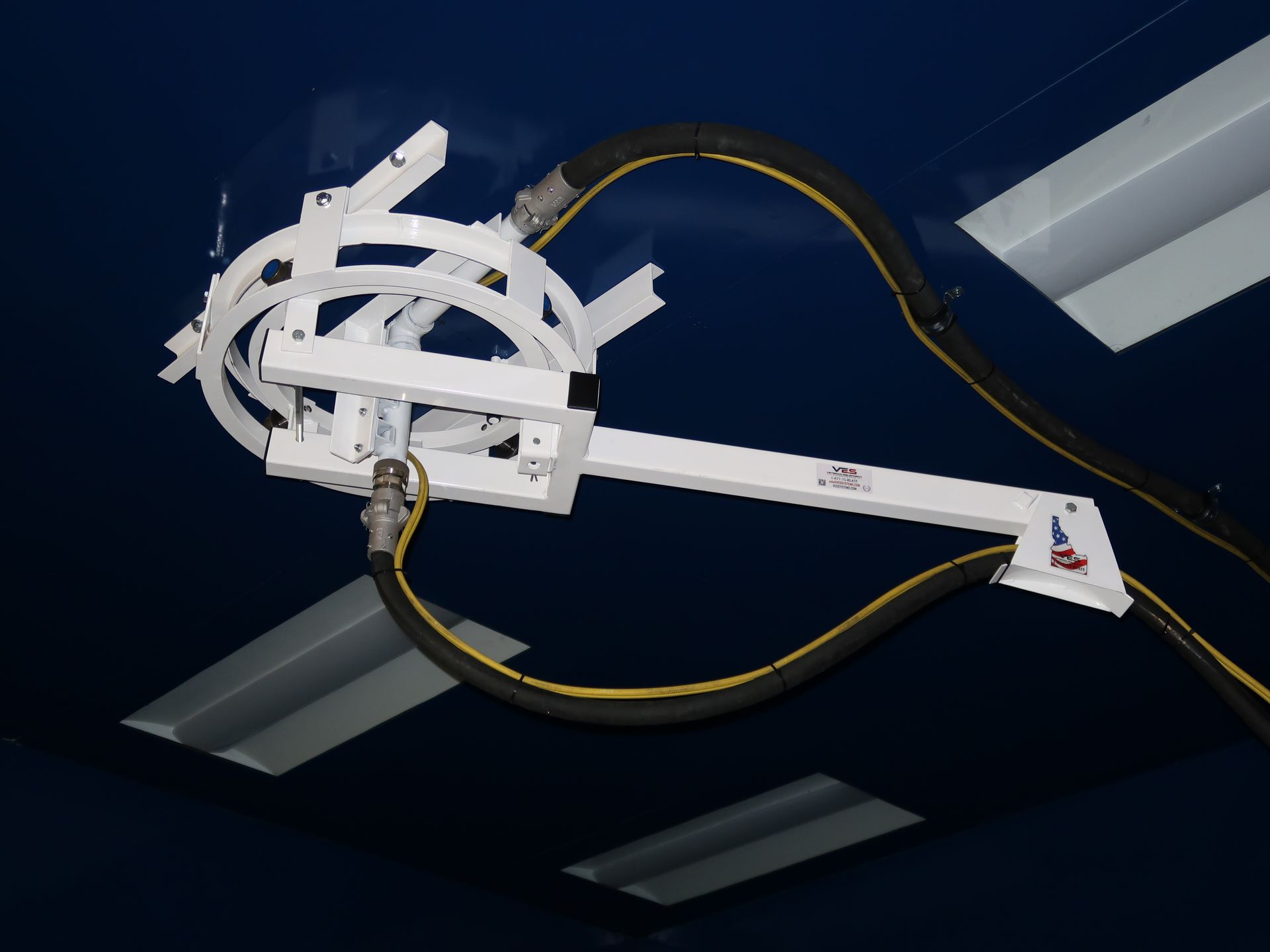

That same approach led to a recent breakthrough in the form of a rotating heavy hose support system, a challenge that had resisted successful engineering for years. This system supports operations in blast rooms and hangar environments. An example is available at https://www.vessystems.com/ blast-booth-accessories.

Purpose remains constant. Myers and Wilbanks do not frame success in terms of market share. They measure it in protected operators, reliable systems, and sustained readiness. Many at VES have military backgrounds and view every deployment as a responsibility to the mission.

Community involvement reflects the same values. VES supports local food banks, law enforcement, and programs assisting women and children escaping domestic violence. One visible example was a bright pink, double-width Raptor cabinet delivered to Dover Air Force Base in support of Breast Cancer Awareness Month.

Beyond aerospace, VES has expanded into mining, oil and gas, and silica-intensive environments where operator exposure carries similar risks. A key growth driver is the company’s NIOSH-compliant air shower, capable of removing up to 85 percent of surface dust in 18 seconds while maintaining negative pressure and HEPA filtration. Currently, only VES offers this level of protection in hazardous particulate applications.

“We are going to stay at the tip of the spear,” Myers says. “There is always more. We are never satisfied.”

That dissatisfaction with the status quo defines VES. Safer operators deliver higher performance. Better engineering eliminates costly overruns. Reliable systems accelerate readiness. Customer satisfaction means exactly what it says. VES continues to raise expectations for how corrosion control environments should operate, one engineered solution at a time.

Why Containerized Paint Booths Outperform Inflatable Systems for Military and Industrial Applications When military maintenance operations require mobile coating capabilities outside fixed facilities, equipment reliability isn't just convenient, it's mission critical. Inflatable paint booths have emerged as a low-cost alternative to traditional spray booths, but their fundamental design limitations create serious compliance risks, safety concerns, and operational failures that can ground aircraft and endanger personnel. If you're responsible for maintaining military equipment, choosing the right mobile paint booth system could mean the difference between sustained readiness and costly downtime. Here's what you need to know about inflatable versus containerized paint booth systems, and why one choice protects your mission while the other puts it at risk. The Appeal (and Reality) of Inflatable Paint Booths Inflatable paint booths look attractive on paper. They promise lower upfront costs, portability, and the flexibility to set up temporary coating operations anywhere you need them. For commercial applications with minimal regulatory oversight, they might suffice. But when you're coating military aircraft, working with hexavalent chromium primers, or operating under NESHAP 319 regulations, "good enough" isn't good enough. Here's what inflatable booth manufacturers don't tell you: Inflatable systems rely on continuous air pressure to maintain structural integrity. That soft-wall construction, typically PVC or vinyl, creates vulnerabilities that become critical failures in real-world military maintenance environments. A single puncture from a ladder, scaffold, hand tool, or aircraft component compromises the entire booth, contaminating the work environment and exposing your personnel to hazardous materials. Even when deployed inside hangars where they're supposedly protected from weather, inflatable booths face constant contact with the very equipment they're meant to contain; rolling toolboxes, air hoses, maintenance stands, and the sharp edges of aircraft components all create puncture risks. And unlike a torn tarp you can patch and forget, a compromised inflatable paint booth creates an immediate environmental and safety violation. The Hidden Compliance Crisis: Hexavalent Chromium Here's the technical reality most inflatable booth manufacturers hope you won't understand: Many military coating operations generate hexavalent chromium (Cr6+) particulates in the 2-3 micron range, particles so small they're invisible to the naked eye but can be deadly over time. This known carcinogen requires strict containment under NESHAP 319 regulations, and the consequences of non-compliance extend far beyond fines. Standard overspray filters cannot reliably capture particulates this small. Many inflatable paint booth systems use basic overspray filters designed for larger particles, typically 10 microns and above. These filters catch the visible paint mist you can see, giving the illusion of effective filtration. But they allow sub-3 micron hexavalent chromium particles to pass right through, exposing your personnel to carcinogenic materials and creating environmental violations you may not discover until someone gets sick years later. The soft-wall construction of inflatable booths compounds this problem. Without rigid walls, you cannot engineer proper airflow patterns or maintain the negative pressure differential required for hazardous material containment. Pressure fluctuations from door openings, wind loading, or minor leaks disrupt capture velocity, allowing contaminated air to escape into the surrounding work area. Translation: Your inflatable booth might look like it's working, but it could be silently exposing your team to cancer-causing materials every single day. Structural Integrity: When "Good Enough" Kills the Mission Military maintenance operations don't happen in controlled laboratory conditions. They happen in hangars full of equipment, on flight lines exposed to weather, and in forward operating environments where "ideal conditions" don't exist. Inflatable paint booths are designed for ideal conditions that rarely materialize in real-world operations. Consider real world scenarios: A maintainer leans a ladder against the booth wall to access an aircraft tail section. The pressure point creates a small tear. Now your booth pressure drops, your airflow pattern collapses, and you've just contaminated your entire paint job with particulates from the surrounding environment. The coating fails specification, the part gets rejected, and your mission timeline just slipped by days, weeks or longer. Or this: You're operating in a region where temperatures swing from freezing nights to scorching days. The PVC material of your inflatable booth expands and contracts, stress points develop, and seams begin to fail. By the time you notice the problem, you've been operating out of compliance for weeks, your personnel have been breathing contaminated air, and you're facing potential regulatory citations that could shut down your entire operation. Containerized paint booth systems eliminate these failure modes entirely. Built inside reinforced ISO containers with 14-gauge steel construction, VES containerized systems deliver permanent structural integrity that doesn't depend on air pressure, doesn't tear when contacted by equipment, and doesn't degrade under temperature extremes. The rigid steel walls eliminate concerns over seam failures, punctures in the structure from interaction with common maintenance behaviors, as well as support proper ducting, stable airflow patterns, and the mechanical systems needed for true NESHAP 319 compliance. The Three-Stage Filtration Array Advantage NESHAP 319 compliance isn't about checking a box, it's about protecting the people who maintain our aircraft and preserving the environment. VES containerized paint booth systems achieve this through engineered three-stage filtration that inflatable systems simply cannot replicate. Stage 1: Primary Filtration Bulk overspray and larger particulates (10+ microns) are captured in the first stage, protecting downstream filters, and extending system life. This is where inflatable booth filtration typically stops in many cases. Stage 2: High-Efficiency Secondary Filtration This is where containerized systems separate themselves from inflatable alternatives. Secondary filters rated MERV 13-16 capture fine particulates in the 2-10 micron range, the size range that includes hexavalent chromium. This stage removes the invisible carcinogens that standard overspray filters miss. Stage 3: Pocket Style Final Filtration The third stage pocket filters in VES NESHAP 319-compliant paint booth systems represent the final barrier for capturing fine and ultra-fine particulates before exhaust air is released to the atmosphere. These high-efficiency filters are specifically engineered to capture hexavalent chromium (Cr6+) particulates at 2-3 microns and smaller, ensuring full compliance with EPA regulations and protecting both personnel and the environment. The result: Air leaving an inflatable booth with standard overspray filters can often times contaminate your environment with the very materials you're trying to contain. Total Cost of Ownership: The $335,000 Mistake Inflatable paint booth manufacturers lead with purchase price. "Why spend $120,000-$150,000 on a containerized system when you can get an inflatable booth for $50,000?" It's a compelling pitch, until you look at what happens over the next ten years. The real cost of inflatable systems: • Initial Purchase: $50,000 • Replacement Cycle: 2-5 years under ideal conditions (less in field use) • Replacements (10 years): $100,000 (two complete replacements) • Maintenance and Repairs: $75,000 (constant patching, blower repairs, component failures) • Energy Costs: $60,000 (continuous blower operation) • Compliance Fines: $50,000 (estimated citations for violations) • Hidden Costs: Mission delays, failed coatings, personnel exposure liability Total 10-Year Cost: $335,000+ The real cost of containerized systems: • Initial Purchase: $125,000 to $150,000 (based on container size and options) • Replacement Cycle: 20+ years (none needed in 10-year horizon) • Maintenance: $25,000 (minimal protected mechanical systems) • Energy Costs: $30,000 (efficient design, no continuous blowers) • Compliance Fines: $0 (proven compliance eliminates risk) • Hidden Costs: Near zero (reliable operation prevents mission delays) Total 10-Year Cost: $205,000 Containerized systems cost ~39% less over ten years while delivering superior performance, guaranteed compliance, and zero unplanned downtime. But the real cost isn't measured in dollars, it's measured in mission readiness and personnel health. What's the cost of grounding an aircraft because a paint booth failure contaminated a critical coating? What's the cost of a workers' compensation claim when a maintainer develops cancer from years of hexavalent chromium exposure? What's the cost to your career when an EPA inspection reveals your operation has been out of compliance for months? Operational Reality: When Equipment Fails, Missions Fail Let's talk about what actually happens when you choose an inflatable paint booth for military operations. Scenario 1: Environmental Failure: It's July in the Southwest. Temperatures hit 115°F on the flight line. Your inflatable booth's PVC material softens in the heat, seams begin to separate, and the structure starts to sag. You've got an aircraft with components that need to be coated and returned to service in 48 hours. Your booth is unusable. The aircraft misses its maintenance window. The mission gets delayed. With a containerized system, you'd be operating normally. Steel doesn't care if it's 115°F or -40°F. Your mission continues. Scenario 2: Structural Failure: You're coating aircraft components in a busy hangar. A forklift operator misjudges clearance and clips your inflatable booth with a raised pallet. The booth tears, pressure drops, and suddenly you're spraying in an uncontrolled environment. Not only is your current coating ruined, but you've just exposed everyone in the hangar to overspray and organic vapors. OSHA gets called. Your operation shuts down for investigation. With a containerized system, the container wins the battle with a misguided raised pallet. Maybe you've got a paint scratch to touch up. Your operation continues. Scenario 3: Compliance Failure: An EPA inspector shows up for a surprise audit. Your inflatable booth has the required overspray filters, so you think you're compliant. The inspector asks about your filtration efficiency at 2-3 microns for hexavalent chromium capture. You can't provide documentation because your filters aren't rated for that particle size. Citation issued. Operations suspended until you can prove compliance. With a containerized system, you hand the inspector your three-stage filtration documentation, pressure differential monitoring logs, and NESHAP 319 compliance certification. Inspection passes. Your operation continues. Deployment Flexibility: Rapid Response When It Matters One argument for inflatable booths is supposed deployment flexibility. "They're portable and quick to set up," the sales pitch goes. Reality tells a different story. Inflatable booth deployment: • Unpack components (multiple pieces) • Assemble frame or anchoring system • Unroll and connect booth material • Set up external blower and filtration • Inflate and test • Connect electrical (often inadequate for hazardous environments) • Setup time: 4-8 hours minimum, often longer • Requires 2-4 people • Weather-dependent (can't set up in high winds or inclement weather) Containerized booth deployment: • Position container on stable surface • Connect utilities (electrical and compressed air) • Install provided external exhaust ducting • Power on and verify systems • Operational time: 4-5 hours • Requires 1-2 people plus equipment operator • Weather-independent But here's the real deployment advantage of containerized systems: You can pre-position them and store them without durability concerns. Standard ISO containers move by truck, rail, ship, or military aircraft (C-17/C-5). You can forward-deploy containerized booths to operating locations before you need them, store them long-term without degradation, and relocate them as missions change. Try storing an inflatable booth for six months in a hot shipping container, if it's still usable when you unpack it, you'll be lucky. Safety and Explosion Protection: Where Cutting Corners Costs Lives Paint booths create environments filled with flammable vapor, organic solvents, and ignition sources. The National Fire Protection Association (NFPA 33) has strict requirements for equipment operating in these conditions, requirements that inflatable booths struggle to meet. Electrical systems in flammable environments must be explosion-proof rated Class I, Division 1 for Groups C and D vapors. This isn't optional. It's life safety. Inflatable booths typically use standard electrical components with minimal explosion protection. Why? Because proper explosion-proof fixtures, wiring, and controls are heavy, rigid, and expensive, characteristics incompatible with lightweight inflatable construction. The soft-wall design also makes proper grounding difficult, increasing static discharge ignition risk. VES containerized systems incorporate Class I, Division 1 explosion-proof electrical systems as standard equipment. Every light fixture, every switch, every electrical connection is rated for flammable vapor environments. The steel structure provides continuous grounding, eliminating static discharge risk. Fire suppression systems can be integrated directly into the container structure. When you're working with materials that can ignite from a spark, "close enough" on electrical safety isn't acceptable. The SDVOSB Advantage: More Than Just a Certification When you choose a containerized paint booth from VES, you're not just buying superior equipment, you're partnering with a Service-Disabled Veteran-Owned Small Business that understands military operations because we've lived them. We know what happens when equipment fails in the field. We know what "mission-critical" actually means. We know that the standards we learned in uniform, attention to detail, refusal to accept "good enough," commitment to the people depending on our work, don't end when we take off the uniform. That's why we engineered containerized systems that eliminate the failure modes we see in inflatable booths. That's why we over-build filtration systems to guarantee compliance even when conditions aren't perfect. That's why we use steel construction that survives real-world abuse instead of materials that fail under routine contact. We build equipment the way we'd want it built if we were still wearing the uniform, because the people using it are still wearing that uniform. What Military Programs Are Learning the Hard Way If you're reading this because your C-130 program, F-16 maintenance operation (or any aircraft for that matter) facility is having problems with inflatable paint booths, you're not alone. We're hearing the same story from programs across all services: • Booths that don't last the promised 3-5 years • Constant repairs and downtime • Compliance concerns that keep environmental officers awake at night • Personnel exposure worries that create liability • Mission delays from equipment failures The programs solving these problems aren't patching inflatable booths or buying better PVC, they're transitioning to containerized systems that eliminate the problems entirely. The Bottom Line: Mission Readiness vs. Mission Risk Every equipment decision comes down to priorities. If your priority is the lowest possible purchase price, inflatable paint booths will always win. But if your priorities are: • Protecting personnel from carcinogenic exposure • Maintaining guaranteed NESHAP 319 compliance • Ensuring mission readiness through reliable equipment • Reducing long-term costs through durable construction • Operating safely in all environmental conditions Then containerized paint booth systems aren't just better, they're the only choice. Making the Right Decision for Your Operation If you're evaluating mobile paint booth options, ask these questions: About Filtration: • What is the capture efficiency at 2-3 microns for hexavalent chromium? • Can the manufacturer provide third-party test data? • How is filtration efficiency maintained as filters load? • What monitoring systems verify continuous compliance? About Structural Integrity: • What happens if the booth is punctured or torn? • Can the structure withstand routine maintenance activity contact? • How does temperature affect structural integrity? • What is the realistic service life under field conditions? About Total Cost: • What is the true 10-year cost including replacements and maintenance? • What are the consequences of compliance failures? • What does mission downtime cost when the booth fails? About Safety: • Are electrical systems properly rated for flammable vapor environments? • How is proper grounding achieved and verified? • Can the booth integrate with fire suppression systems? • What happens to personnel safety if the booth fails during operation? If the answers don't give you complete confidence, you're looking at the wrong system. Don't Risk Your Mission on Equipment That Fails When You Need It Most The choice between inflatable and containerized paint booths isn't about budget, it's about priorities. Inflatable systems offer lower initial cost in exchange for compliance risk, operational unreliability, and personnel exposure. Containerized systems deliver mission assurance through proven performance. When lives depend on aircraft readiness and personnel safety is non-negotiable, the decision is clear. Request your consultation today and discover why programs nationwide are transitioning from inflatable to containerized paint booth systems. Veteran Equipment Sales provides containerized NESHAP 319-compliant paint booth systems that deliver: • Three-stage NESHAP 319 filtration • Steel construction surviving 20+ years in all environments • Rapid deployment with 2-4 hour setup time • Class I, Division 1 explosion-proof electrical systems • Proven compliance eliminating regulatory risk • Total cost of ownership lower than inflatable alternatives Contact us for: • Technical specifications and compliance documentation • Total cost of ownership analysis for your specific application • Site assessment and deployment planning Veteran Equipment Systems and Sales: A Service-Disabled Veteran-Owned Small Business, with Factories Located in Nampa and Fruitland Idaho Website: www.vessystems.com Related Articles You Might Find Helpful: • Understanding NESHAP 319 Compliance: What Every Maintenance Officer Should Know • The Hidden Danger of Hexavalent Chromium in Military Coating Operations • Total Cost of Ownership: Why the Cheapest Paint Booth Costs the Most Author Bio: Daniel Myers is the founder and president of Veteran Equipment Sales, a Service-Disabled Veteran-Owned Small Business specializing in NESHAP 319-compliant paint booths, precision blast systems, and Hexavalent Chromium Elimination/Abatement Products for military and industrial applications. With 20 years of military service, 15 years of military depot experience, and 10 years leading VES, Dan brings firsthand understanding of the equipment reliability and personnel protection standards required in defense and commercial operations.